Specializing in Cold Formed Parts

Reduce your manufacturing costs by switching to cold headed products.

Request QuotesSc Advantage

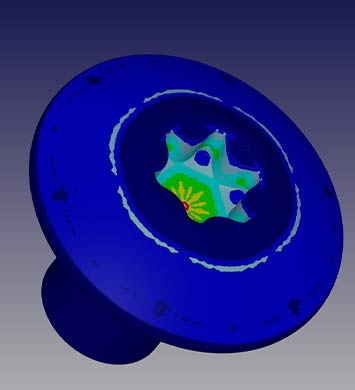

Our cold forming technology offers several advantages over traditional machining methods:

- Elimination of material waste, improving cost-efficiency

- Enhanced product strength, reliability, and durability

- Ability to produce complex shapes and designs in a single operation

- Maintenance of close tolerances for precise fit and compatibility

Engineered Fasteners

At Specialty Screw Corp., we pride ourselves on our ability to create truly engineered fasteners. Our expertise in this area stems from several key factors:

Experienced Design Team

Our tool designers and engineers utilize state-of-the-art AutoCAD software to create precise, custom fastener designs tailored to your specific needs.

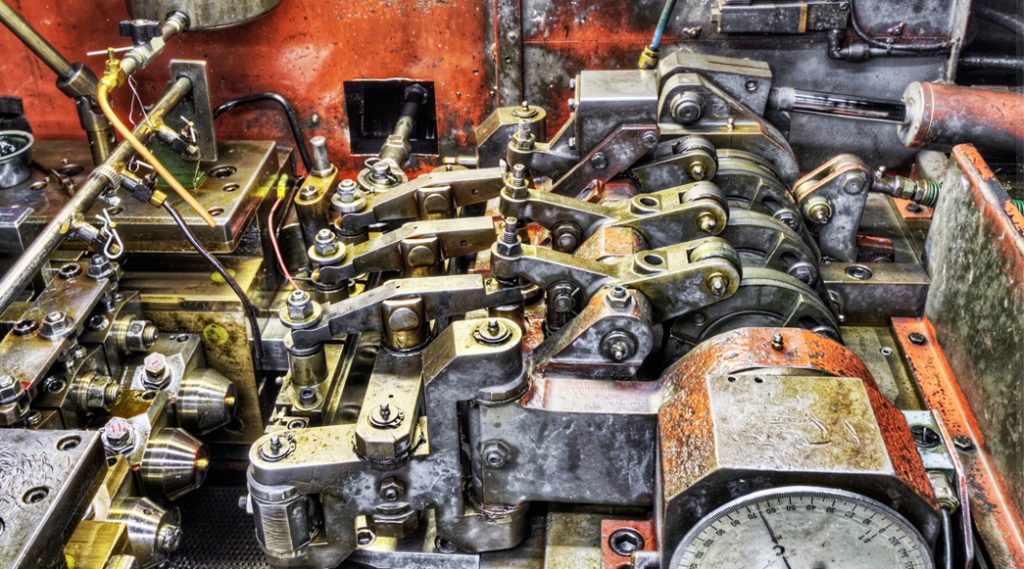

Versatile Cold Heading Capabilities

We offer a wide size range and variety of cold headers, allowing us to produce fasteners in numerous sizes and configurations.

Comprehensive In-House Secondary Operations

Our extensive in-house secondary equipment enables us to perform a wide range of post-forming operations, ensuring your fasteners meet exact specifications.

On-Site Tool Room

Our facility includes an on-site tool room with advanced EDM (Electrical Discharge Machining) capabilities, allowing for rapid prototyping and tooling modifications.

Licensed Technologies

As a licensed manufacturer of MAThread® and TORX/TORXPLUS®, we can incorporate these innovative designs into your custom fasteners.

Our cold forming technology offers several advantages over traditional machining methods:

- Elimination of material waste, improving cost-efficiency

- Enhanced product strength, reliability, and durability

- Ability to produce complex shapes and designs in a single operation

- Maintenance of close tolerances for precise fit and compatibility

Corporate Values

As a privately held company, Specialty Screw Corp. remains dedicated to providing its customers with unparalleled quality and service in the fastening marketplace. This commitment to excellence has solidified the company's position as an industry leader and trusted partner for businesses worldwide.

Industries Served

At Specialty Screw Corp., we pride ourselves on our versatility and expertise in serving a wide range of industries with our high-quality fasteners and engineered components. Our solutions are tailored to meet the unique Automotive

As a leader in the automotive fastener industry, we provide innovative solutions for:

- Vehicle body and chassis components

- Powertrain systems

- Interior and exterior trim

- Safety systems

- Electrical components

Our automotive fasteners meet or exceed stringent industry standards, including IATF 16949:2016 certification.

Our commitment to precision and reliability ensures that our automotive fasteners contribute to the safety, performance, and longevity of vehicles across the globe.

Awards and Recognition

At Specialty Screw Corp., we take immense pride in our commitment to excellence, innovation, and responsible business practices. Our dedication has been recognized through numerous prestigious awards and certifications over the years, spanning areas such as supplier performance, environmental stewardship, employee welfare, and quality management.

These accolades, bestowed upon us by industry leaders, environmental organizations, and community partners, reflect our ongoing efforts to maintain the highest standards in manufacturing, sustainability, and workplace culture.

From our Bronze Supplier Performance Award to our repeated recognition as a Healthy Manufacturer, each honor serves as a testament to our team's hard work and our company's unwavering commitment to continuous improvement. As we celebrate these achievements, we remain focused on our mission to provide exceptional value to our customers, employees, and community, driving innovation and sustainability in the fastening and engineered component industry.

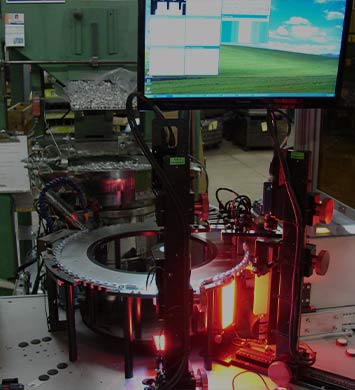

Quality Assurance

Our commitment to quality is unwavering. We employ rigorous inspection and sorting processes to ensure that every part meets or exceeds customer specifications. Our quality management system is certified to ISO 9001:2015 and IATF 16949:2016 standards, guaranteeing consistent, high-quality output.

Custom Solutions

Our engineering team works closely with customers to develop custom fastening solutions tailored to specific application requirements. From material selection to design optimization and prototyping, we offer end-to-end support to ensure the perfect fastener for every need.

At Specialty Screw Corp., our comprehensive capabilities, cutting-edge technology, and commitment to quality position us as a premier partner for all your fastening needs. Whether you require standard parts or complex, custom-engineered solutions, our team is ready to deliver excellence in every fastener we produce.

Quality Assurance

Specialty Screw Corp. maintains rigorous quality standards and employs innovative technologies to deliver superior fastening solutions:

Quality Management Certifications

- IATF 16949:2016: Demonstrates compliance with the International Automotive Task Force's quality management system standard for the automotive industry.

- ISO 9001:2015: Validates our robust quality management system meeting international standards.

Government and Defense Qualifications

- CAGE Code: Possesses a Commercial and Government Entity Code, facilitating participation in government contracting.

- DLA Certified: Recognized as a Defense Logistics Agency certified supplier, meeting rigorous standards for supplying to U.S. military and government organizations.

Innovative Fastener Technologies

- MAThread® and MATpoint®: Patented thread designs that prevent cross-threading and improve fastener alignment during assembly.

- Torx®: Licensed to produce this high-performance drive system that provides optimal torque transfer and reduces tool slippage.

These certifications and technologies demonstrate our commitment to quality, reliability, and innovation in serving both commercial and government sectors. They provide our customers with confidence in our ability to deliver high-quality fasteners and engineered components that meet or exceed industry standards.