Products

At Specialty Screw Corp., we pride ourselves on our ability to create truly engineered fasteners.

Engineered Fasteners

At Specialty Screw Corp., we pride ourselves on our ability to create truly engineered fasteners. Our expertise in this area stems from several key factors:

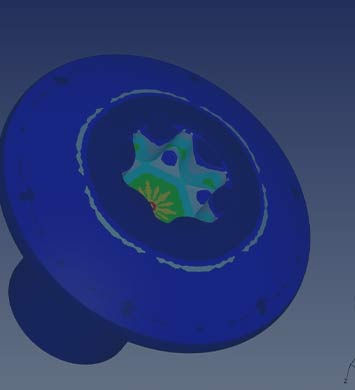

Experienced Design Team

Our tool designers and engineers utilize state-of-the-art AutoCAD software to create precise, custom fastener designs tailored to your specific needs.

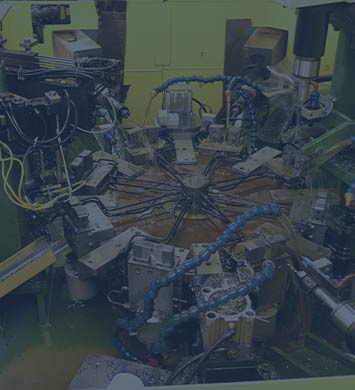

Versatile Cold Heading Capabilities

We offer a wide size range and variety of cold headers, allowing us to produce fasteners in numerous sizes and configurations.

Comprehensive In-House Secondary Operations

Our extensive in-house secondary equipment enables us to perform a wide range of post-forming operations, ensuring your fasteners meet exact specifications.

On-Site Tool Room

Our facility includes an on-site tool room with advanced EDM (Electrical Discharge Machining) capabilities, allowing for rapid prototyping and tooling modifications.

Licensed Technologies

As a licensed manufacturer of MAThread® and TORX/TORXPLUS®, we can incorporate these innovative designs into your custom fasteners.

Our cold forming technology offers several advantages over traditional machining methods:

- Elimination of material waste, improving cost-efficiency

- Enhanced product strength, reliability, and durability

- Ability to produce complex shapes and designs in a single operation

- Maintenance of close tolerances for precise fit and compatibility

Engineered Fasteners

At Specialty Screw Corp., we pride ourselves on our ability to create truly engineered fasteners. Our expertise in this area stems from several key factors:

Experienced Design Team

Our tool designers and engineers utilize state-of-the-art AutoCAD software to create precise, custom fastener designs tailored to your specific needs.

Versatile Cold Heading Capabilities

We offer a wide size range and variety of cold headers, allowing us to produce fasteners in numerous sizes and configurations.

Comprehensive In-House Secondary Operations

Our extensive in-house secondary equipment enables us to perform a wide range of post-forming operations, ensuring your fasteners meet exact specifications.

On-Site Tool Room

Our facility includes an on-site tool room with advanced EDM (Electrical Discharge Machining) capabilities, allowing for rapid prototyping and tooling modifications.

Licensed Technologies

As a licensed manufacturer of MAThread® and TORX/TORXPLUS®, we can incorporate these innovative designs into your custom fasteners.

Our cold forming technology offers several advantages over traditional machining methods:

- Elimination of material waste, improving cost-efficiency

- Enhanced product strength, reliability, and durability

- Ability to produce complex shapes and designs in a single operation

- Maintenance of close tolerances for precise fit and compatibility

Applications Assistance

Our team of experts is ready to assist you in selecting the ideal fastener solution for your application. We offer comprehensive support throughout the design and manufacturing process, ensuring that your fasteners meet all required specifications and performance criteria.

Non-Automotive Applications

While Specialty Screw Corp. has a strong presence in the automotive industry, we also excel in providing fastener solutions for a wide range of non-automotive applications. Our expertise extends to various industries, including:

Our team works closely with buyers and engineers across these industries to develop fastener solutions that meet specific strength, tensile, plating, and tolerance requirements.

Firearms

- Firing pins

- Bolt stop pins

- Sight screws

- Specialized grip screws

- Medallions

Hand Tools

- Specialized hex and shoulder bolts

- TORX/TORXPLUS screws

- Flex bar screws

- Rivets

Building Hardware

- Window components (knob pins, bolt step limiters, cam drivers)

- Door hardware (plunger stop holders, specialized studs, spring hex bolts)

Electrical Storage

- Stepped bolts

- Anti-rotation head bolts

- Power feed studs

- Stationary terminals

Additional Industries

- Small engines

- Furniture

- Manufacturing tooling parts

- Infrastructure

- Heating and cooling systems

- Recreational equipment

- Self-Aligning Design: MAThread® incorporates a unique self-aligning feature into the lead-in point and starting threads of the fastener.

- Industry Recognition: MAThread® is listed in General Motors Worldwide Standards, is being incorporated into Chrysler/Mercedes Benz standards, and is used by Ford Motor Company.

- Proven Performance: With over 1 billion installations, MAThread® has demonstrated its ability to:

- Eliminate cross-threading

- Ease assembly processes

- Align components automatically

- Overcome issues with clogged internal threads

- How It Works:

- The versatile design allows for various point shapes to suit specific applications

- As threads make contact, the patented anti-cross thread feature cams over the female thread

- The MAThread® forces thread helix alignment every time, ensuring smooth and easy driving

- Specifications:

- Available in metric sizes M3.5-M16 and inch sizes #6-5/8

- Lengths up to 5" (per customer requirements)

- Compatible with all head styles, finishes, and materials (including soft copper)

MAThread® technology makes every assembly job user-friendly, offering unmatched anti-cross-thread performance and the ability to overcome issues like paint buildup in internal threads.

MAThread® Technology

Specialty Screw Corp. is proud to be a licensed manufacturer of MAThread® and MATpoint® fasteners. This innovative technology offers significant advantages in assembly applications:

TORX® Technology

The TORX® Drive System was specifically designed to provide a simple, cost-effective solution to the problems inherent in the process of installing and removing fasteners. Used in a multitude of industries, the TORX® Drive System can enhance product reliability, increase productivity and reduce total assembly costs - all if which are keys to remaining competitive in today’s marketplace.

FEATURES:

- 15 ̊ drive angle

- Straight, vertical sidewalls

- Broad contact surface

- Standard drive tools for screw sizes inch (#000 - 1.375”) and metric (0.9mm - 36mm)

- Wide variety of sizes ranging from T1-T100, E4-E44

BENEFITS:

- Greater depth of tool and lobe engagement while minimizing tool slippage

- No camout forces are created to push the driver up

- Since camout is virtually eliminated, little to no end load is required

- High torque transfer and drastically reduced radial forces resulting in longer tool life

- Driving forces spread over a broad surface

- Ability to convert to metric later without a tooling change

- Quality enhanced through single sourced gaging program

VARIATIONS:

- Internal TORX® Drive

- External TORX® Drive

- TORX® TAMPER RESISTANT Drive

- TORXSTEMTM Double-Ended Studs

- DUAL DRIVE Systems

- AUDITORX® Drive System

- ClearDrive® Feature

IDEAL INDUSTRIES:

- Automotive

- AerospaceCommercial Truck

- Consumer Electronics

- Building & Construction

- Many Other Industries

Registered Trademark

Specialty Screw Corp. takes pride in its registered trademark, which represents our commitment to quality and innovation in the fastener industry:

- Trademark Details:

- Registered to Specialty Screw Corp.

- Address: 2801 Huffman Boulevard, Rockford, Illinois 61103

- Registration Number: 1,919,247

- Registration Date: September 19, 1995

- Class: 6 (US CLS. 2, 12, 13, 14, 23, 25, and 50)

- Product Category: Cold headed metal fasteners, screws, bolts, studs, rivets, and hinge pins

Our registered trademark, Specialty Screw, is a symbol of our dedication to producing high-quality, innovative fastener solutions. It represents our long-standing commitment to excellence in the industry and our ability to meet the diverse needs of our customers across various sectors.

By choosing Specialty Screw Corp. for your fastener needs, you're partnering with a company that combines decades of experience, cutting-edge technology, and a commitment to quality. Whether you require standard fasteners or custom-engineered solutions, our team is ready to deliver excellence in every product we manufacture.

Custom Solutions

Our engineering team works closely with customers to develop custom fastening solutions tailored to specific application requirements. From material selection to design optimization and prototyping, we offer end-to-end support to ensure the perfect fastener for every need.

At Specialty Screw Corp., our comprehensive capabilities, cutting-edge technology, and commitment to quality position us as a premier partner for all your fastening needs. Whether you require standard parts or complex, custom-engineered solutions, our team is ready to deliver excellence in every fastener we produce.